-

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

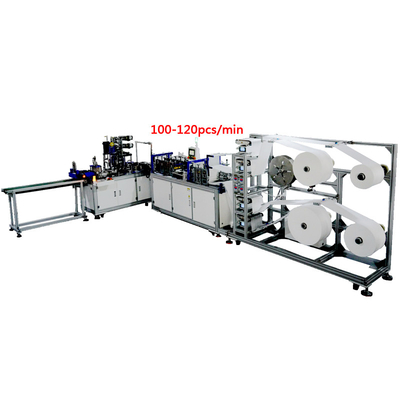

80-120 pieces/min Fashionable Design Fully Automatic Kf94 Fish Type Mask Making Machine

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Other | After Warranty Service | Online Support, Field Maintenance And Repair Service, Spare Parts, Video Technical Support |

|---|---|---|---|

| Automatic Grade | Full-automatic | After-sales Service Provided | Field Installation, Commissioning And Training, Free Spare Parts, Video Technical Support, Online Support, Field Maintenance And Repair Service |

| Key Selling Points | Famous Brand PLC | Mask Material | Non-woven Fabrics |

| Keywords | Ultrasonic Face Mask Making Machine | Function | Automatic Disposable Mask Production Line |

Global Warranty Cheap kf94mask welding machine kf94 mask ear loop welding machine automatic kf94 fish type mask packing machine

The speed of Chuangying kf94 adult mask machine, kf94 child mask machine, and kf94 pattern positioning mask machine has increased to 150-180 pieces per minute. The product qualification rate is 99.99%. Speed, appearance and other details can be customized according to requirements. The steel structure of the whole machine is sturdy and durable, and the ultrasonic high-power 15k4200w is not easy to damage. Easy to use. Can be exported to all parts of the world. ce certification. Global joint guarantee, preferential prices, 430 units have been sold, and have been unanimously recognized and praised by customers at home and abroad. You are welcome to consult and negotiate. The mask machine is divided into: flat mask machine, kf94 mask machine, cup mask machine, flat fish mask machine, elastic ear band mask machine, kn95 mask machine. Various positioning pattern mask machines, customized machines according to the mask style you need. We specialize in customizing special mask machines. Packaging machines are divided into: bag-feeding packaging machine, four-side sealing packaging machine, three-side sealing packaging machine, counting machine and so on. And there are mask appearance inspection equipment, packaging machine, cartoning machine, sealing machine, and fully automated unmanned production mask line can be customized. The company established a mask factory in May 2021, and can now produce and export various masks. Welcome your consultation and inspection.

![]()

![]()

| Equipment capacity | Equipment capacity |

| Equipment installation size | 5518(L)*2530(W)*2141(H) |

| equipment weight | 1200KG |

| Equipment voltage | 220V /50/60Hz |

| Rated current of equipment | 60A |

![]()

![]()

![]()

![]()

![]()

![]()

Hello, please don't feel strange when you see words like mine. I am the boss of this mask machine enterprise. I have been doing research and development of machinery and equipment for ten years. I didn't expect the sudden outbreak of the epidemic this year to transform our company into mask machines. I have always been very strict in doing things, and so has the mask machine designed by our company. I have participated in the control of our machines from design to purchase related raw materials. Every detail of the machine is done with great precision. The machine runs stably and is easy to operate. There is a Korean interface. At present, plane mask machines have been made for more than 1,000 years this year, and KF94 South Korea has exported more than 200 units. The factory still has 100 semi-finished products in stock. Can be assembled, installed, debugged and shipped at any time. The fastest delivery speed can be one to two days. Special custom-made mask appearance, 10 days delivery.

common problem

Q: Are you a factory or a trading company?

A: We are a factory with import and export license.

Q: Where is your factory?

A: Our factory is located in Guangdong, China.

Q: How long is the warranty period?

Answer: The shelf life is one year.

Q: How about the installation? Do you have after-sales service?

Answer: South Korea and Vietnam have after-sales service and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install it in this way. Just install the four screws of the connector of the film sticking machine and the earband machine, learn to install the cloth and then operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: Why should we choose your company?

A:1-A company with CE certificate certification.

2-Various production lines, flat mask machine, kf94 mask machine, cup mask machine, flat fish mask machine, elastic ear band mask machine, kn95 mask machine, various positioning pattern mask machine, customized machine according to the mask style you need.

3- Advanced technical support and strict quality control system.

4- Efficient and timely services such as email, WeChat, WhatsApp, etc.

Excerpted from the Internet, for reference only

Basic parameters: Name: willow leaf (fish type) mask machine

Model Custom

Specification L3500×W800×H1700mm

Machine output 80pcs/min

Voltage single-phase 220V/50/60Hz

Air pressure without air pressure

Power 3.8KW

The weight of the whole machine is 850KG Working video

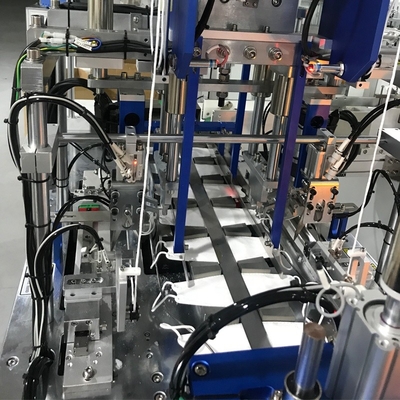

Detailed structure introduction: 1. Main body all-in-one machine 1. Nose bridge metal wire output mechanism

2. Melting cloth feeding rack

3. Nose bridge metal wire cutting mechanism

4. Welding mechanism

5. Fabric forming and cutting mechanism

6. Punching mechanism

7. Waste discharge mechanism

8. Fabric stacking mechanism

9. Fabric edge trimming and adjusting mechanism

10. Fabric flattening and adjusting mechanism

11. Fabric stacking mechanism

12. Raw material export mechanism

13. Secondary welding and fabric adjustment mechanism

14. Secondary welding mechanism

15. Fabric cutting and adjusting mechanism

16. Cutting mechanism

17. Discharging mechanism

2, film feeder 3, ear strap welding machine

1. Ear strap input mechanism

2. Earband welding mechanism

3. Earband cutting mechanism

4. Earband output mechanism

5. Earband cutting mechanism

4. Details show the metal wire output mechanism of the bridge of the nose

1. Nose bridge wire discharge baffle to limit the active area of nose bridge wire

2. Fixed shaft, fixed nose bridge wire material

3. Runner, nose bridge wire feeding wheel (adjustable)

4. Brake wheel, which rotates with the fixed shaft

5. Brake pads, when the brake wheel is in contact with the brake pads, it will contact the brakes. Wheels brake the machine due to resistance

6. Contact block, contact the brake block according to the rotation and swing of the swing arm

7. Swing arm to make the swing device rotate

Fabric feeding mechanism

1. Fixed shaft support plate for installing the fixed shaft

2. The fabric output support shaft is used to support the fabric output

3. Nose bridge wire transmission support rod, supporting wire guide wheel

4. Godet wheel for wire guide

5. Fabric output detection, used to detect the presence or absence of fabric, it includes a sensor for fabric detection

6. Aluminum bracket, the main support of the bracket

7. Fabric transition support rod for fabric output transition

8. Casters, easy to move the rack

9. Goblet, rack installation and fixed nose bridge wire cutting mechanism

1. Nose bridge wire transition wheel, used to feed the nose wire and play a transition role

2. The nose bridge wire transfer wheel, which transfers the wire in a rotating manner

3. The nose bridge wire scissors, the rotary roller controls the wire cutter to cut the wire

4. Nose bridge wire stopper to ensure that the wire will not be deviated

5. The transmission sprocket provides power for the entire nose bridge metal wire transportation. The welding formation mechanism

1. Ultrasonic transducer, providing welding energy for fusion welding wheel

2. Limit block, adjust the welding wheel to the appropriate position for limit control

3. Welding wheel slider, fixed in the bearing to control the rotation of the welding wheel

4. Adjust the screw, adjust the slider to move up and down, adjust the friction of the rotating welding wheel

5. The limit handwheel, adjust the welding wheel to the appropriate position, and then fix the limit to avoid the screw swinging

6. Adjust the handwheel, turn the handwheel to adjust the pressure of the welding wheel

7. Ultrasonic mold, fusion welding the multi-layer fabric of the mask together

8. Investment welding roller, also known as investment welding wheel, is a pattern mask for investment welding

9. Support shaft to support the limit block to fix the boards on both sides

10. Transition roller, transition roller for cloth

11. Gearbox, a mechanism that provides driving power for the welding wheel. Pleating mechanism 1. Pleating roller, which folds the fabric with the cooperation of the pleating plate

2. Handwheel to adjust and move the entire pleating mechanism

3. Slider, the whole pleating mechanism is fixed on the slider

4 transition rollers for smooth cloth movement

5. Pleating board, fold the fabric under the cooperation of pleating rollers

6. Fix the stop, adjust and move the pleated plate output mechanism

1. Ball handle, pull this handle to lift the upper roller

2. Connecting rod block, connecting rod block between the swing rod and the rotating shaft

3. The lifting limit block is used to control the position of the roller shaft.

4. Flange, fix the lower support shaft and inner bearing to ensure the rotation of the lower support shaft

5. Lower idler, the chain drives idler to rotate

6. The upper roller, the two gears mesh, the lower gear drives the upper gear

7. Adjust the screw to adjust the pressure of the pressure spring

8. Pressure spring, the contact between the two rollers can be adjusted according to the thickness of the material

9. Move the slider to control the upper roller to slide up and down on the side plate

10. Rotate the shaft to do driven rotary motion

11. Transmission gear, providing power for materials, traction device, fabric adjustment mechanism

1. Turn the hand wheel, turn the hand wheel to drive the adjusting screw to rotate

2. Adjust the screw, after turning the screw, the inner shaft of the roller can be moved up and down

3. The inner shaft of the roller, which is used to adjust the inner shaft of the roller

4. Adjust the roller and adjust the position of the cloth by moving up and down

5. Cloth transition roller, make the cloth move smoothly and waste output mechanism

1. Waste transition belt to transport excess waste

2. Mask compression roller, press the mask

3. Adjust the shaft to adjust the tension of the belt

4. Drive roller to provide power for belt conveying

5. Drive sprocket to transmit power to the whole mechanism

6. Compression spring, according to the thickness of the material,

The contact pressure between the two rollers can be adjusted

7. Adjust the screw to adjust the pressure of the pressure spring

8. Driven roller, passively rotating conveying roller at the bottom

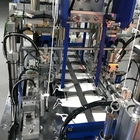

9. Drive the roller to make the conveying roller rotate right below the ear rope conveying mechanism

1. The ear rope conveying motor is controlled by the ear rope tension sensor after detection to determine the power supply and start and stop

2. Ear rope guide, the introduction port of the ear rope

3. The ear rope is passed through the driven wheel, and the ear rope is conveyed by the driven wheel

4. Ear cord tension sensor, a detector that detects ear cord tension

5. Ear rope tensioning floating wheel, the tensioning force is controlled by the lifting and lowering of the ear rope floating wheel

6. Ear rope conveying drive wheel, driving wheel for ear rope conveying

7. Ear rope guide groove, ear rope discharge guide groove, ear rope cutting mechanism

1. The scissors avoid the cylinder to prevent the scissors from drying the ear rope.

2. Scissors open and close the cylinder to cut the ear rope

3. Ear cord fixing device to lock the ear cord so that it does not move

4. Scissors, play the role of cutting the ear rope

5.Earring traction guide rail, guide reciprocating sliding

6. The ear cord clamping cylinder is used to clamp the ear cord

7. Connect the block to connect the cylinder with the ear rope clamping cylinder

8. Cylinder, can move to provide power ear rope rotating feeding mechanism

1. The ear rope lifting cylinder controls the earring clamping device to move up and down to the fuse welding position

2. Thin-walled cylinder, push the whole mechanism to rotate

3. Guide rails, guide components to slide back and forth

4. The ear rope rotation detection sensor detects the rotation position of the earring rotation motor and uses it as a signal to control the rotation and stop of the motor

5. Metal plate, a device to detect rotation and wobble

6. Earring electric rotating machinery, used to control the rotation of the ear rope clamping device

7. The ear rope clamps the cylinder to clamp or loosen the ear rope

8. Ear rope clamping claw ear rope fusion welding mechanism

1. Ultrasonic lifting and sliding device, which can move the welding device up and down

2. Fusion welding head, fusion welding head for ear cord

3. The pressure plate, which acts as a pressure plate and a fixed mask

4. Ultrasonic mold, which can generate ultrasonic waves for welding

5. Ultrasonic transducer, ultrasonic generating device

6. Mask clamping device, clamp the mask and move it. Advertising space investment:

Those things about the mask machine, the public account to attract investment:

People find machines, machines find materials, materials find people, and so on. Undertake commercial advertisements of various mask industry chains. (Low price, quick effect), at present, the price of mask machine equipment has been greatly reduced, the old equipment is about to be replaced, and the market is changing and will be greatly reshuffled. The mask machine industry has no successor, and the poor sales have faced a bottleneck. The market is iterating, and the core technology is facing an upgrade. Contact us now to provide a platform. Advertising space investment! ! !

Mr. Liu: 15857176418 (WeChat synchronization)! Manufacturers, orders, technology, installation and commissioning, supply chain, customers, etc.

Pay attention to those things about the mask machine

WeChat public account

One-stop service for resources such as the full set of mask industry chain,

My diligence saves you worry!

Share it and let more people see it! Click below to read the original text for more exciting

N95 mask machine external nose bridge to internal nose bridge solution...

8 common faults and solutions of N95 mask machine...

Installation and commissioning operation guide of flat mask punching machine...

Flat mask machine-unwinding rack and filming mechanism installation and debugging experience...

N95 mask machine - detailed description of the structure of technical explanation...

Introduction to the debugging method of the mask machine - sunflower collection...

How long can the popular N95 mask machine last... More originals, please pay attention to the WeChat public account, your encouragement is the driving force for me to move forward...