-

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

n95 mask packaging machines automatic mask packaging machine kn95 packaging packaging mask machine

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops | After Warranty Service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

|---|---|---|---|

| Application | MEDICAL, Machinery & Hardware, Textiles | Automatic Grade | Automatic |

| Driven Type | Mechanical | After-sales Service Provided | Online Support, Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service |

| Key Selling Points | Easy To Operate | Core Components | PLC, Pressure Vessel, Gear, Motor, Engine, Bearing, Gearbox, Pump |

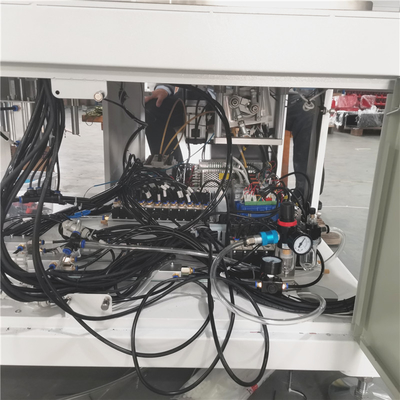

1. Equipment introduction

The packaging machine adopts the method of heat sealing, which is fully automatic from taking material to bagging and sealing, effectively reducing the need for manual operation. The overall appearance of the equipment is beautiful and elegant, and the signal processing is performed by the programmable controller PLC, including automatic alarm and fault prompt functions. At the same time, it adopts man-machine interface control, which is easy to operate and easy to maintain. The packaged finished product has a clear seal and good sealing performance.

![]()

Equipment parameters

1. Equipment installation size: 1600 (L)* 1200 (W)* 1300(H)

2. Equipment weight: 300KG

3. Working power supply: AC220V 50/60Hz

4. Working air source: 0.5-0.7MPa

5. Power: 7KW

6. Noise: no more than 80dB

![]()

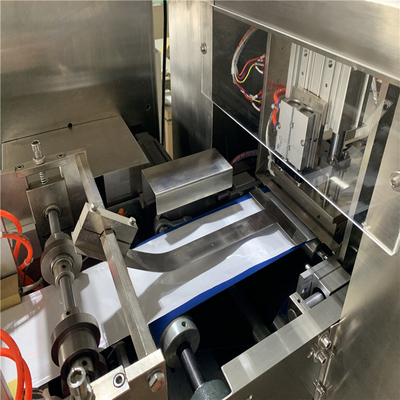

3, Equipment structure

1. Control system: using Xinjie PLC, with better stability; 7-inch touch screen, clearer and not accidentally touched;

2. Sealing system: heat sealing mode sealing, convenient and easy to debug;

3. Mask opening system: three suction cups open the bag at the same time, making the opening of the bag larger and more stable;

4. Mask bag feeding system: compatible with width 140-180mm, length 210-280mm;

5. Mask feeding system: Compatible with all kinds of masks, the quantity is 3-10 pieces

6. Mask into bag system: The mask gripper feeds the mask into the mask bag

4. basic parts

| number | name | Manufacturer) |

| 1 | lead plane | custom made |

| 2 | Rack | custom made |

| 3 | servo motor | Lead shine Xinie |

| 4 | air cylinder | SMC |

| 5 | PLC controller | Xinie |

| 6 | touch screen | Artrlch |

| 7 | button | YIJIA |

| 8 | switching power supply | Jin Zhuo yuan |

| 9 | photoelectric sensor | Dokawa |

All information and materials (including text, data, charts, pictures, etc.) described in this book belong to the intellectual property rights of the company. Without permission, any plagiarism and citation are infringements.

Exhibition photos

Exhibition photos

Exhibition photos

The company has obtained more than 20 kinds of national new patents and software copyrights, which are in full compliance with export standards. Chuangying has complete processing equipment and efficient technical team; with its deep technical development strength, complete product guarantee system, sincere pre-sales advice and perfect after-sales service, it integratesdomestic and foreign electromechanical control technology into one. One of the automation service providers in the mask machine industry,home appliance industry, and sensor industry provides a strong backing for the high-efficiency, high-quality, and high-precision development of the machinery industry.

Falt mask machine production workshop

Kn95 mask machine production workshop

Four-side sealing packaging machine production workshopTo bag packaging machine production workshop

To bag packaging machine production workshop

preciseness, quality first and service second are our company's business philosophy. I hope the epidemic situation in South Korea

and the world will end as soon as possible. I hope we can work together for win-win results

FAQ

The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to

customer service for details.

2. The machine I want is too ?

inconsistent with what you showed on the Internet. 3.Can I do it?

Yes, you need to provide machine pictures and finished mask pictures.

4.what should I do if I buy a machine and Iwon’t install it back?South Korea and Vietnam have after-sales and can be installed on

site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only

need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and

operate normally. The company will be equipped with text version and video version of the whole teaching.

5. How long is the warranty period?

The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company

provides new parts.

After-sales service description

research and development of machinery and equipment for ten years. I didn't expect the sudden outbreak of the epidemic this year

to transform our company into mask machines. I have always been very strict in doing things, and so has the mask machine designed

by our company. I have participated in the control of our machines from design to purchase related raw materials. Every detail of

the machine is done with great precision. The machine runs stably and is easy to operate. There is a Korean interface. At present,

plane mask machines have been made for more than 1,000 years this year, and KF94 South Korea has exported more than 200 units. The

factory still has 100 semi-finished products in stock. Can be assembled, installed, debugged and shipped at any time. The fastest

delivery speed can be one to two days. Special custom-made mask appearance, 10 days delivery. KN95 has produced a total of 300

units, and there are still 80 units in stock, which are on sale at a special price. 70-80 pcs per minute. Details can be found on

the website about the introduction of relevant machines. The KF94 packaging machine we made was followed by the machines bought

from South Korea and improved many shortcomings of the past machines. We are rigorous and professional in the mask machine

industry. I would like to make a special mention of South Korea's door-to-door installation service. It usually takes 10-15 days

from the time you place an order to the time when the goods arrive. Shipping from Qingdao port, transportation time: 3-5 days.

After delivery, we will arrange the time for after-sales personnel to install in advance and train your employees how to operate

one-stop service. After-sales warranty period of one year, if you have any questions, you can contact the company's after-sales

customer service in time. The company will arrange personnel to carry out on-site maintenance in the first place.

The specific packaging process of the machine is as follows: 1st loading the bag, 2nd opening the bag, 3rd filling material, 4th sealing, 5th printing the production date. Such automatic, intelligent, production efficiency, production quality, full-featured, high-tech fully automatic bag feeding and packaging machines can more meet the production needs of enterprises. This machine adopts advanced computer electrical control system, with friendly man-machine interface, convenient operation, and is equipped with a detection device, which can detect that the filling device does not perform filling when the machine has no packaging or the packaging bag is not opened, and the heat sealing device does not Sealed to avoid wasting packaging materials and raw materials.

1. It can withstand high work pressure and high-yield work requirements, but workers cannot do it. If they work around the clock, employees will work for a long time, but it will reduce work efficiency, and the shift system will increase labor input and cost input. !

2. Save labor, the working process of the automatic bag-feeding vacuum packaging machine is completed by mechanical equipment, which saves labor for enterprises and can solve the difficult problem of recruitment in today's society.

3. The work efficiency is unmatched by traditional manual work. Because the equipment is mechanized, there will be no fatigue and no manual operation is required, so compared with traditional manual packaging, its work efficiency is higher.

4. The operation is convenient and fast, controlled by an intelligent control system, and can complete multiple processes at one time: automatic bag picking, coding, bag opening, filling, vacuuming, and sealing. 5. The machine can realize a multi-purpose machine! The bag width and sealing part can be adjusted at one time, as long as the bag packaging size is within the range of bag width 70mm-120mm and bag length 60mm-180mm; when manufacturing equipment, in order to achieve multiple uses for one machine, engineering and technical personnel Improvements can be made to adjust the bag width and the position of the sealing line at one time, providing convenience for enterprises to pack various types of products, saving operation time and increasing production capacity.

This kind of packaging machine has replaced manual packaging and has become the right-hand man on the packaging production line. Compared with the general packaging equipment, the current automatic bag-feeding packaging machine is a relatively classic processing equipment. The production cost is low, and it can be produced in large quantities, which largely satisfies the high-yield and high-quality production tasks of the enterprise. Help the rapid development of enterprises. Major enterprises are very recognized for the technology of automatic bag feeding and packaging machine.

With the continuous improvement of bag-type packaging machine technology, this machine has been recognized by more and more food companies and has been applied to more and more enterprises' production. Hope this little article is helpful to you all!