-

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

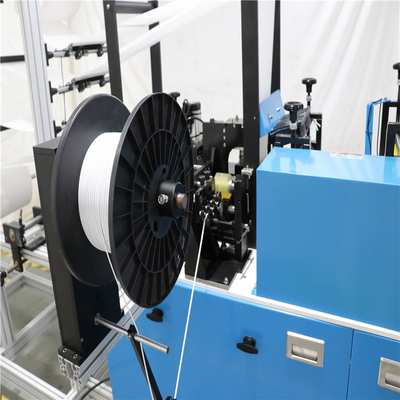

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

220V 15W KN95 Foldable Mask Machine PLC Head Loop Mask Machine

| Applicable Industries | Manufacturing Plant | Showroom Location | South Korea |

|---|---|---|---|

| Condition | New | Voltage | 220V, 380V |

| Power | 15W | Weight | 1750 KG |

| Warranty | 1 Year | Mask Types | Kn95 |

| High Light | 15W KN95 Foldable Mask Machine,220V KN95 Foldable Mask Machine,PLC Head Loop Mask Machine |

||

180 tablets per minute at high speed n95 foldable mask machine n95 mask machine head loop mask machine n95 biaozan

The speed of Chuangying kf94 adult mask machine, kf94 child mask machine, and kf94 pattern positioning mask machine has increased to 150-180 pieces per minute. The product qualification rate is 99.99%. Speed, appearance and other details can be customized according to requirements. The steel structure of the whole machine is sturdy and durable, and the ultrasonic high-power 15k4200w is not easy to damage. Easy to use. Can be exported to all parts of the world. ce certification. Global joint guarantee, preferential prices, 430 units have been sold, and have been unanimously recognized and praised by customers at home and abroad.

You are welcome to consult and negotiate. The mask machine is divided into: flat mask machine, kf94 mask machine, cup mask machine, flat fish mask machine, elastic ear band mask machine, kn95 mask machine. Various positioning pattern mask machines, customized machines according to the mask style you need. We specialize in customizing special mask machines. Packaging machines are divided into: bag-feeding packaging machine, four-side sealing packaging machine, three-side sealing packaging machine,counting machine and so on. And there are mask appearance inspection equipment, packaging machine, cartoning machine, sealing machine, and fully automated unmanned production mask line can be customized. The company established a mask factory in May 2021, and can now produce and export various masks. Welcome your consultation and inspection.

![]()

![]()

| After-sales Service Provided | Field maintenance and repair service |

| Port | Shenzhen port, Qingdao port |

| Mask Material | Non-woven Fabrics |

| Dimension(L*W*H) | 8500MM*1500MM*2000MM |

| Automatic Grade | Full-automatic |

| Production Capacity | 110-130 pcs/min |

![]()

Q: How long is the delivery time?

Answer: The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to customer service for details.

Question: The machine I want is too inconsistent with what you showed on the Internet. Can I do it?

Answer: Yes, you need to provide machine pictures and finished mask pictures.

Question: What should I do if I buy a machine and I won’t install it back?

Answer: South Korea and Vietnam have after-sales and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: How long is the warranty period?

Answer: The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company provides new parts.

The following information comes from the Internet for reference only

Fusion process of kn95 printing machine and sewing machine earmuffs

The left and right ear belt melting mechanism and the pad printing mechanism are connected by screws, and they can move together along the guide rails on the frame. The driving source is the servo motor + screw mechanism under the frame: the structure of the special pad printing process:

The second is the wiring board connection process.

Binaural band wire drawing joint mechanism

Three-cut ear strap device

The UV part is used to adjust the angle and position of the cut ear straps.

Arrangement order:

→The cylinder pushes the front mechanism and stretches it towards the ear straps;

→After the scissors limit block touches the above-mentioned pressing claw block (see the figure below), the air cylinder continues to push. At this time, the pressing block pushes the scissors to the closed state, thereby cutting the ear straps;

→When carriage return, due to the action of the spring on the fader, the fader and the shear limiting block are separated, and the shears return to the open state.

Mark the process.

The labeling mechanism and the internal labeling of the labeling mask are basically unmanned in this process, so detailed analysis will not be made here.

Mask cutting and disposal procedures.

The mask can be folded.

The function of this step is to fold the mask that was originally laid on the plane in half, and then enter the roller-1.

Working position of unpowered rollers.

The rotary swing handle drives the transmission shaft to rotate, and then drives the screw to rotate through the umbrella gear transmission mechanism, so as to achieve the purpose of adjusting the position of the moving roller.

Working position of kn95 mask hot-pressing edge sealing.

The screw drive module is used to drive the reciprocating movement of the entire mechanism to ensure that there is no relative displacement with the mask; the mask is folded, and the embossing wire mold (one of the three-piece set) and ultrasonic heating are used to heat-press the edge.

kn95 turning ear strap positioning

Before turning over, the ear straps are all facing downwards. This turning action is to turn the middle turning ear straps upwards.

Five, kn95 cutting workpiece.

There are two rollers on the station, one is a hob (one of three sets), and the other is a knife pillow. This kind of mask is mainly cut to shape according to the designed shape and size.

The output position of the mask.

The unloading belt takes the mask out, and at the same time discharges the cut waste from the following path: Roller-1→Roller-2→Roller 3→Roller 4→driving roller & pressing roller for discharge.

The power of the chip collecting mechanism, that is, the power shaft, is transmitted through this bevel gear mechanism.

Obviously, the power source is two servo motors + reducer, and the power is transmitted to each process through a power shaft.

The overall mechanism consists of multiple frames. When they are separated, in order not to disassemble the entire power shaft, a cross universal telescopic coupling is used at the frame butt joint.