-

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

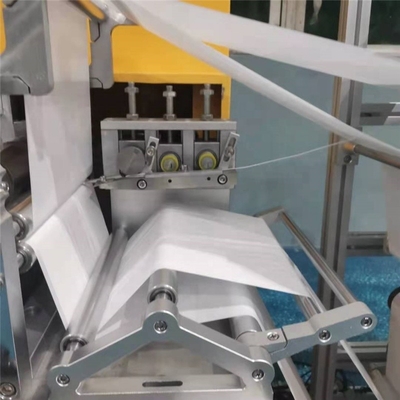

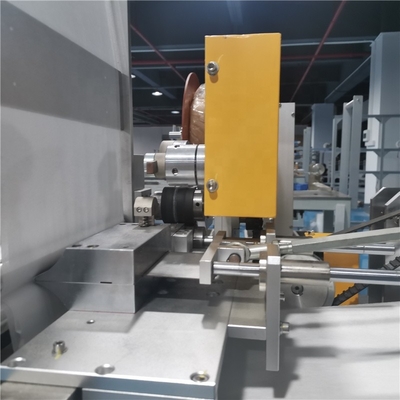

220V Ultrasonic Ear Loop Welding Machine 15kW Nonwoven Converting Machinery

| Applicable Industries | Manufacturing Plant | Showroom Location | South Korea |

|---|---|---|---|

| Condition | New | Automatic Grade | Full-automatic |

| Voltage | 220V, 380V | Power | 15kW |

| Weight | 1500 KG | Warranty | 1 Year |

| Year | 2021 | Production Capacity | 120 Pcs/min |

| Key Selling Points | Easy To Operate | Mask Types | Flat |

| Mask Material | Non-woven Fabrics | Machine Type | Disposable Nonwoven Machinery |

| Type | Nonwoven Fabric Line | Port | Shenzhen Port, Qingdao Port |

| High Light | 220V Ultrasonic Ear Loop Welding Machine,15kW Nonwoven Converting Machinery,Ultrasonic Ear Loop Welding Machine 15kW |

||

100 pcs/min mask n95 machine n95 mask making machine n95 weld machine

The speed of Chuangying kf94 adult mask machine, kf94 child mask machine, and kf94 pattern positioning mask machine has increased to 150-180 pieces per minute. The product qualification rate is 99.99%. Speed, appearance and other details can be customized according to requirements. The steel structure of the whole machine is sturdy and durable, and the ultrasonic high-power 15k4200w is not easy to damage. Easy to use. Can be exported to all parts of the world. ce certification. Global joint guarantee, preferential prices, 430 units have been sold, and have been unanimously recognized and praised by customers at home and abroad.

You are welcome to consult and negotiate. The mask machine is divided into: flat mask machine, kf94 mask machine, cup mask machine, flat fish mask machine, elastic ear band mask machine, kn95 mask machine. Various positioning pattern mask machines, customized machines according to the mask style you need. We specialize in customizing special mask machines. Packaging machines are divided into: bag-feeding packaging machine, four-side sealing packaging machine, three-side sealing packaging machine,counting machine and so on. And there are mask appearance inspection equipment, packaging machine, cartoning machine, sealing machine, and fully automated unmanned production mask line can be customized. The company established a mask factory in May 2021, and can now produce and export various masks. Welcome your consultation and inspection.

| Application | Making Disposable Face Mask |

| Usage | Non Woven Products Making |

| After-sales Service Provided | Field installation, commissioning and training |

| Final products | Disposable Fabric Face Mask |

| Dimension(L*W*H) | 8500MM*1500MM*2000MM |

| Product name | Mask Making Machine |

![]()

FAQ

Q: How long is the delivery time?

Answer: The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to customer service for details.

Question: The machine I want is too inconsistent with what you showed on the Internet. Can I do it?

Answer: Yes, you need to provide machine pictures and finished mask pictures.

Question: What should I do if I buy a machine and I won’t install it back?

Answer: South Korea and Vietnam have after-sales and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: How long is the warranty period?

Answer: The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company provides new parts.

The following information comes from the Internet for reference only

Mainly engaged in the development and production of industrial machine vision and automation equipment, and has certain advantages in the field of mechanical automation manufacturing. During the transformation process, the production business of the mask machine has developed rapidly. Soon after the outbreak of the disease, Chuangying Times Technology Co., Ltd. developed a high-speed flat mask machine production line and KN95 series mask machine. The production cycle is 5-7 days. If you are interested, you can go to KN95 automatic mask production equipment. The KN95 automatic mask production equipment was favored by the market as soon as it was launched.

Chuangying Times Technology KN95 automatic mask production equipment adopts a full-board frame structure, the overall is easy to disassemble, the appearance is painted, the electronic control is a touch screen man-machine interface operation, with automatic pad printing, folding molding, automatic ear welding (other wiring required), Equipment servo feeding and positioning purchased KN95 automatic mask machine. After the outbreak of the epidemic, the company quickly expanded its production capacity. Specializing in the KN95 mask production line, you can visit the factory to see the machine at any time, and the price is reasonable. The manufacturer directly provides quality assurance, and the delivery is accurate and honest. There are ultrasonic mask spot welding machine, manual mask spot welding machine and automatic mask spot welding machine. The models are complete and the supply is sufficient. Please contact us directly.

If you need to buy a KN95 mask sticking machine with a built-in nose bridge, please contact us directly.

It has an automatic slicer, including a mask body machine, a mask conveying mechanism and two shunting mechanisms. The mask conveying mechanism is arranged at the discharge port of the mask main body machine, and is used to convey the mask produced by the mask main body machine. Pre-sales service: The mask sales staff will introduce the functions and uses of the mask products in detail, and provide consultation on factory layout, personnel training and capital budgeting according to the different situations of the customers.

A series of non-standard automated production equipment, such as mask machine, ear strap machine, cup noodle machine, engraving machine, metal, etc. Ultrasonic welding and automatic edge banding technology are used to achieve composite molding. Multilayer materials are the main equipment for this process. The cover host is an automated production equipment for multi-layer covers.