-

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

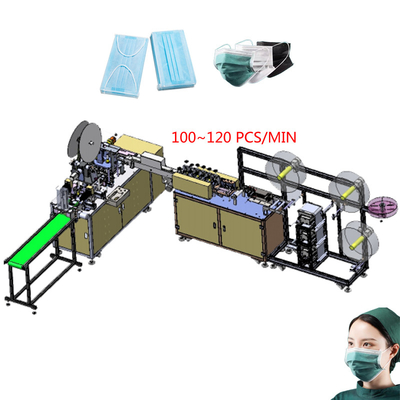

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

High Speed 160pcs/Min 3 Ply Ultrasonic Earloop Welding Machine

| Place of Origin | Guangdong, China |

|---|---|

| Brand Name | Win |

| Certification | ce |

| Model Number | Inner ear mask machine |

| Minimum Order Quantity | 1 set |

| Price | $9,000.00/Sets 1-4 Sets |

| Packaging Details | Pack the wooden box after vacuum packing |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 150 Set/Sets per Month |

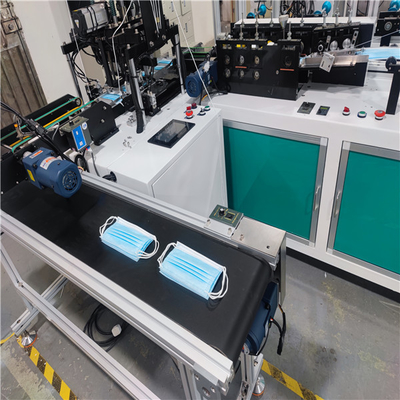

| Machine Type | Disposable Nonwoven Machinery | Dimension(L*W*H) | 2300mm*4900MM*2200MM |

|---|---|---|---|

| Application | Making Disposable Face Mask | Applicable Industries | Manufacturing Plant |

| Function | Making Surgical Face Mask | Showroom Location | South Korea |

| Condition | New | Automatic Grade | Full-automatic |

| Voltage | 220V | Power | 22kW |

| Usage | Non Woven Products Making | Warranty | 1 Year |

| Production Capacity | 120 Pcs/min | Mask Types | Flat |

| Product Name | Mask Making Machine | Final Products | Disposable Fabric Face Mask |

| Keywords | Nonwoven Fabric Proction Line | Name | Automatic Face Mask Line |

| Type | Nonwoven Fabric Line | ||

| High Light | 3 Ply Ultrasonic Earloop Welding Machine,160pcs/Min Ultrasonic Earloop Welding Machine,160pcs earloop welding machine |

||

The high-speed mask machine produces 150 to 180 pieces per minute per minute. This machine can produce adult masks and children masks at the same time. There is also an upgraded version of the positioning mask machine to produce printed masks. High-speed elastic earband machine, 300 to 500 pieces per minute. The whole machine is small and does not take up space. Stable and easy operation. The price is favorable, and it is unanimously recognized and praised by customers at home and abroad. The company's global warranty for one year. Remote video guidance is available after sale. The machines have installation videos. Welcome your guidance and consultation.

|

Power supply

|

AC 220V ±10% 50Hz 16A.

|

|

Dimensions

|

2300MM × 4900MM × 2200MM.

|

|

The quality of the whole machine

|

(approximately) 1000Kg.

|

|

Weight

|

1000kg

|

|

Expansion performance

|

can be connected to packaging equipment.

|

|

Use environment

|

ambient temperature 10-30 degrees Celsius, relative humidity less than 80%, no condensation, no dust, no corrosive gas, no strong

vibration source around the machine. |

Q: How long is the delivery time?

Answer: The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to customer service for details.

Question: The machine I want is too inconsistent with what you showed on the Internet. Can I do it?

Answer: Yes, you need to provide machine pictures and finished mask pictures.

Question: What should I do if I buy a machine and I won’t install it back?

Answer: South Korea and Vietnam have after-sales and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: How long is the warranty period?

Answer: The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company provides new parts.

The following information comes from the Internet for reference only

The country is currently at a critical time in the fight against the new crown pneumonia epidemic, and flat masks have undoubtedly become the most practical and important line of defense in this campaign. Whether it is front-line medical staff, ordinary householders or office workers in all walks of life, they all need this "armor" shelter;

China is the world's largest producer of masks, with a daily production capacity of more than 20 million flat masks. But when a product becomes a daily necessities for 1.4 billion people, the almost impossible to quantify demand figures make the original production capacity drop in the bucket.

As a professional manufacturer of automation equipment, Chuangying is based on its own professional field and technical advantages, and has the courage to take responsibility, actively innovate and develop and design flat mask machines and automatic production equipment to make its own contribution to the fight against the epidemic.

Machine features of automatic strapping flat mask machine

1. The frame is made of aluminum alloy and stainless steel, and the appearance is light and beautiful without rust.

2. Automatic counting, which can effectively control production efficiency and production progress.

3. Frequency conversion control can adjust the operating speed of the equipment according to actual needs.

4. Pull the barrel to feed the material, the positioning is more accurate, the width of the raw material can be controlled to the minimum, and the cost is saved.

5. The length and size of the finished product are uniformly controlled, with a deviation of ±1mm, which can effectively control the length of the finished product.

6. The equipment has a high degree of automation and low requirements on the operating staff. It only needs to discharge the materials and arrange the finished products.

7. Stable performance and easy operation.

8. The automatic ultrasonic welding wheel is made of imported high-quality steel, with long mold life, wear-resistant and durable.

Precautions for machine installation of automatic strapping flat mask machine

1. Unpack the package and check the surface and parts of the equipment for signs of damage. Check whether the screws are loose, whether the electrical connectors are locked, and whether the accessories are complete.

2. The flat face mask machine equipment should be placed on a flat hard ground. The mask strapping machine is required to be at least 0.5 meters away from the heat source, and it is necessary to ensure that there is at least 1 meter in the front and rear of the mask strapping machine and at least 1 meter in the left and right sides for easy operation.

3. Check the voltage requirements of the sign on the back of the vibrating box, and ensure that the system is well grounded.

4. Connect the device to the power supply, and make sure to turn off the power switch first.

The voltage requirement of this machine: AC220V, 50~60Hz

![]()

![]()