-

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

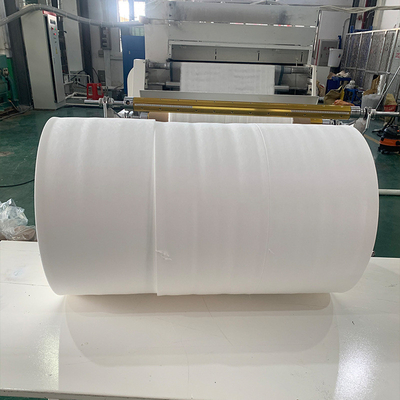

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

1 Set Non Woven Fabric PE Laminate 3 Layer Protective

| Application | Agriculture Cover | Product Name | Non Woven Fabric |

|---|---|---|---|

| Name | 100% PolyPROPYLENE Spunbonded Nonwoven Fabric | Keywords | 100 PP Non Woven Fabric |

| High Light | non woven melt blown filter cloth,3 Layer melt blown filter fabric,PE Laminate non woven melt blown fabric |

||

![]()

| Packing | Roll Packing |

| Technology | Meltblown Pp Nonwoven Fabric |

| Usage | Medicl |

| Type | Hot-stamping Non-woven Fabric |

| item | value |

| Supply Type | In-Stock Items |

| Pattern | SOLIDS |

| Feature | Waterproof, Breathable, Anti-Bacteria, Shrink-Resistant, Water Resistant, Wrinkle Resistant, Oilproof |

| Material | 100% Polypropylene |

| Weight | 25g/40g |

![]()

![]()

![]()

![]()

Hello, please don't feel strange when you see words like mine. I am the boss of this mask machine enterprise. I have been doing research and development of machinery and equipment for ten years. I didn't expect the sudden outbreak of the epidemic this year to transform our company into mask machines. I have always been very strict in doing things, and so has the mask machine designed by our company. I have participated in the control of our machines from design to purchase related raw materials. Every detail of the machine is done with great precision. The machine runs stably and is easy to operate. There is a Korean interface. At present, plane mask machines have been made for more than 1,000 years this year, and KF94 South Korea has exported more than 200 units. The factory still has 100 semi-finished products in stock. Can be assembled, installed, debugged and shipped at any time. The fastest delivery speed can be one to two days. Special custom-made mask appearance, 10 days delivery.

common problem

Q: Are you a factory or a trading company?

A: We are a factory with import and export license.

Q: Where is your factory?

A: Our factory is located in Guangdong, China.

Q: How long is the warranty period?

Answer: The shelf life is one year.

Q: How about the installation? Do you have after-sales service?

Answer: South Korea and Vietnam have after-sales service and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install it in this way. Just install the four screws of the connector of the film sticking machine and the earband machine, learn to install the cloth and then operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: Why should we choose your company?

A:1-A company with CE certificate certification.

2-Various production lines, flat mask machine, kf94 mask machine, cup mask machine, flat fish mask machine, elastic ear band mask machine, kn95 mask machine, various positioning pattern mask machine, customized machine according to the mask style you need.

3- Advanced technical support and strict quality control system.

4- Efficient and timely services such as email, WeChat, WhatsApp, etc.

Excerpted from the Internet, for reference only

Meltblown cloth is the "heart" of the mask and is used for the filter layer in the middle of the medical mask. It has good filterability, barrier properties, heat preservation and adsorption properties. With the spread of the new crown epidemic, the shortage of meltblown cloth has become more prominent, and the price has continued to rise - from 18,000 yuan / ton before the epidemic to 200,000 yuan / ton at the end of February, and doubled again to 520,000 yuan / ton in early March. ton, the price increased by 29 times. A few days ago, the State Administration for Market Regulation has disclosed many typical cases of driving up the price of meltblown cloth. Among them, a company specializing in meltblown cloth in Jiangsu, the price of meltblown cloth was 45,000 yuan per ton on January 28, and then gradually increased from 60,000 yuan per ton. Yuan, 90,000 and 150,000 yuan all the way up to the highest price of 560,000 yuan per ton. Meltblown cloth production capacity increased In early April, Sinopec officially announced that the meltblown cloth production line with an annual output of 500 tons was successfully put into operation at the Sinopec Yizheng Chemical Fiber Plant. It is expected that all 16 production lines of Sinopec will be put into operation in May, with an annual production capacity of over 10,000 tons and the ability to process more than 10 billion disposable medical masks. By then, Sinopec is expected to become the largest meltblown cloth manufacturer in China and even the world. Previously, Sinopec built 16 meltblown cloth production lines in two phases, including 4 in Yanshan Petrochemical and 12 in Yizheng Chemical Fiber—among them, 2 meltblown cloth production lines in the first phase of Yanshan Petrochemical were put into operation on March 8, and the first phase of Yizheng Chemical Fiber was put into operation. The meltblown cloth production line was successively completed and put into operation in mid-April. According to the production capacity of central enterprises determined by the State-owned Assets Supervision and Administration Commission of the State Council, Sinopec, SINOMACH and other enterprises have switched production to increase production, and the production of meltblown cloth has increased rapidly. Among them, CHTC Jiahua, a subsidiary of SINOMACH, has switched its production line to melt blown cloth through emergency transformation, and its production capacity has been rapidly increased to 30 tons per day. Up to now, the daily supply of meltblown cloth by central enterprises has reached 42.5 tons, and the cumulative production and supply of more than 1,000 tons of meltblown cloth can be used to produce 1 billion masks. It is understood that the new 20 production lines of Sinopec and PetroChina will reach production in April, and the daily production capacity of meltblown cloth of central enterprises is expected to exceed 70 tons.