-

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

n95 mask 4 side packaging machines rotary type lf94 mask packaging machine kf94 mask packaging machine

| PLC | Xinjie | Temperature System | Omron |

|---|---|---|---|

| Switching Power Supply | Ming Wei | Single-phase Leakage Protection Switch | Chint |

| The Electromagnetic Valve | AirTAC | Magnetic Switch | AirTAC |

The advantages of this mask packaging machine and the difference between ordinary packaging machines

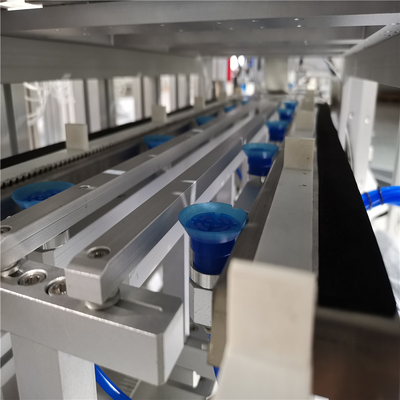

1. When the bottom suction mask and packaging bag are convenient for workers to operate and use, the packaging machine can be in the running state without stopping, which greatly increases the production capacity by 20%.

2. The suction cup is more stable.

3. The bagging position has high accuracy and stability, and the bagging yield is increased to 98%-100%.

4. When the mask is bagged, because it is a downdraft bagging, there will be no occasional entanglement of the ear straps of the mask.

![]()

![]()

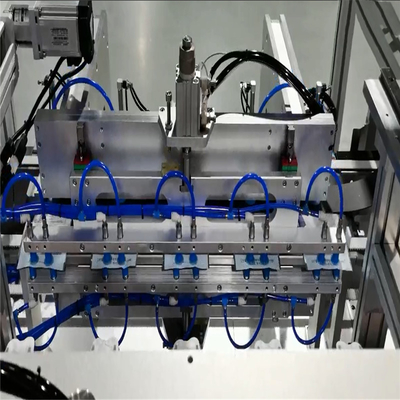

1. Mask bag heat sealing temperature system

2. Heat sealing of the mask bag

3. Heat sealing tightening device

4. Manipulator for feeding and bagging of masks

5. Bagging mask lifting group

6. Human-machine interface

7. Mask bag opening group

8. Mask conveyor belt

9. Mask feeding box

10. Packing bag material box

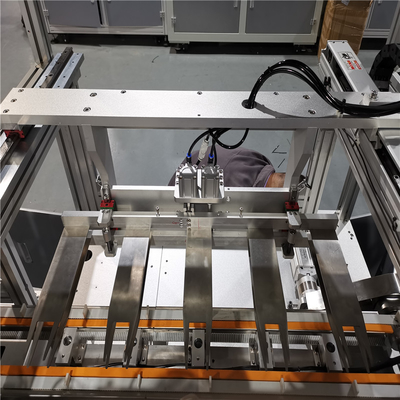

| Equipment Name | KF94 3D Mask Packing Machine |

| Device model | JMPM-04 |

| JMPM-04 | Floor type rollers move and fix foot cups |

| power supply | AC380V±5%; 50Hz/60Hz |

| Environmental requirements | No flammable, explosive and corrosive gases 25℃±5℃; 40—85%RH |

| Rate of qualified products | 98-100% (except non-native factors) |

![]()

![]()

![]()

﹡The mask material box adopts aluminum alloy and stainless steel structure, which is beautiful and elegant.

﹡The size of the material box of the mask machine can be adjusted, which is suitable for KF94 masks of various shapes.

﹡Equipped with 5 material boxes, the mask is taken out by pulling down, and the mask is taken out stably and reliably.

﹡Using the method of putting a mask on the top, adding a mask without stopping the machine, greatly improving the utilization rate of the equipment.

![]()

![]()

![]()

![]()

![]()

![]()

﹡Independent heat sealing buffer mechanism to ensure stable sealing, precise and stable.

﹡The height of each sealing welding head is independently adjustable, and the operation and maintenance are convenient and simple.

﹡The thermal welding head is equipped with an OMRON temperature controller, and the temperature error of the welding head is controlled within ±5ºC.

All information and materials (including text, data, charts, pictures, etc.) described in this book belong to the intellectual property rights of the company. Without permission, any plagiarism and citation are infringements.

Exhibition photos

Exhibition photos

Exhibition photos

The company has obtained more than 20 kinds of national new patents and software copyrights, which are in full compliance with export standards. Chuangying has complete processing equipment and efficient technical team; with its deep technical development strength, complete product guarantee system, sincere pre-sales advice and perfect after-sales service, it integratesdomestic and foreign electromechanical control technology into one. One of the automation service providers in the mask machine industry,home appliance industry, and sensor industry provides a strong backing for the high-efficiency, high-quality, and high-precision development of the machinery industry.

Falt mask machine production workshop

Kn95 mask machine production workshop

Four-side sealing packaging machine production workshopTo bag packaging machine production workshop

To bag packaging machine production workshop

preciseness, quality first and service second are our company's business philosophy. I hope the epidemic situation in South Korea

and the world will end as soon as possible. I hope we can work together for win-win results

FAQ

The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to

customer service for details.

2. The machine I want is too ?

inconsistent with what you showed on the Internet. 3.Can I do it?

Yes, you need to provide machine pictures and finished mask pictures.

4.what should I do if I buy a machine and Iwon’t install it back?South Korea and Vietnam have after-sales and can be installed on

site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only

need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and

operate normally. The company will be equipped with text version and video version of the whole teaching.

5. How long is the warranty period?

The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company

provides new parts.

After-sales service description

research and development of machinery and equipment for ten years. I didn't expect the sudden outbreak of the epidemic this year

to transform our company into mask machines. I have always been very strict in doing things, and so has the mask machine designed

by our company. I have participated in the control of our machines from design to purchase related raw materials. Every detail of

the machine is done with great precision. The machine runs stably and is easy to operate. There is a Korean interface. At present,

plane mask machines have been made for more than 1,000 years this year, and KF94 South Korea has exported more than 200 units. The

factory still has 100 semi-finished products in stock. Can be assembled, installed, debugged and shipped at any time. The fastest

delivery speed can be one to two days. Special custom-made mask appearance, 10 days delivery. KN95 has produced a total of 300

units, and there are still 80 units in stock, which are on sale at a special price. 70-80 pcs per minute. Details can be found on

the website about the introduction of relevant machines. The KF94 packaging machine we made was followed by the machines bought

from South Korea and improved many shortcomings of the past machines. We are rigorous and professional in the mask machine

industry. I would like to make a special mention of South Korea's door-to-door installation service. It usually takes 10-15 days

from the time you place an order to the time when the goods arrive. Shipping from Qingdao port, transportation time: 3-5 days.

After delivery, we will arrange the time for after-sales personnel to install in advance and train your employees how to operate

one-stop service. After-sales warranty period of one year, if you have any questions, you can contact the company's after-sales

customer service in time. The company will arrange personnel to carry out on-site maintenance in the first place.

When the total thickness of the package lined with Bre is 80~90m, the temperature of the hot rod should be 170~180, and the total thickness should be 85~180.

At 100 microns, the temperature should be controlled between 180 and 200 degrees. As the thickness of the package increases, the hot rod temperature should increase accordingly.

bag packing machine

Second: the heat sealing speed is too fast

The reason for the seal failure is also related to the speed of the sealer. The speed is too fast, and the bag has not been heated, and it is pulled and transferred to the cold press for processing, which does not meet the quality requirements of the hot rod.

Third: the cold extrusion rubber tire pressure is not suitable

The spring must clamp when adjusting the pressure.

Fourth: quality problems of packaging bags

Poor sealing is also related to the quality of the bag. The composite lining treated by the new crown is not uniform, the effect is not good, and it is suitable.

The seal cannot be sealed. It's rare, but when it does, the product is out. The seal is a damp and dirty bag.

Sealed ships are not strong either.

In short, in order to solve the problem that the bag packaging machine cannot be completely heat-sealed, the heat-sealing temperature can be appropriately increased, the heat-sealing speed can be reduced, and the cold-pressing can be improved.