-

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

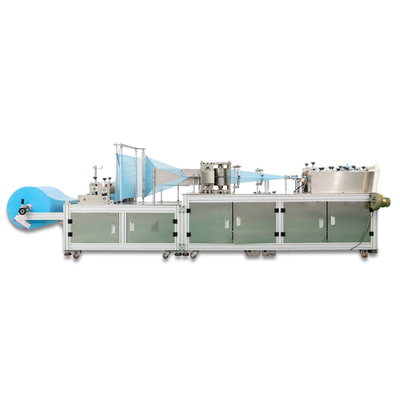

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

High Speed Bouffant Cap Making Machine Automatic Thermostat Control

| Dimensions | 3800(L)×980(W)×1100(H)mm | Adaptable Material | Non-woven Fabric (9-10g/m2) Rubber Band Model (30-40 Yarn Wrapping) |

|---|---|---|---|

| Rated Voltage | 220V±5% | Rated Power | 3Kw |

| High Light | high speed bouffant cap making machine,thermostat control bouffant cap making machine,automatic disposable bouffant cap making machine |

||

High speed bouffant cap making machine plastic PE cap disposable hat making machine

Bar Cap Making Machine Instructions

The company independently developed "non-woven bar cap", which is the first manufacturer of elastic non-woven head cover.

Special machinery, the products are suitable for hospitals or dust-free industries, etc. The machine is stainless steel structure, independent

The electrical control box only needs one person to operate, from feeding to forming, counting and collecting to complete automatic control.

The system can produce up to 200 pieces per minute.

![]()

◆ High stability, excellent performance and low failure rate

◆ Stainless steel structure, independent electrical control box, compact machine, small rest volume

◆ The surface parts are all chrome-plated, and the cover parts are made of stainless steel, which is beautiful and clean

◆ Adjustable ultrasonic welding

◆ One machine is changeable, changing molds can produce bar caps of various specifications

◆ Electronic counting

◆ Automatic shutdown protection for broken material / broken ribs

![]()

![]()

![]()

![]()

|

Specifications of bar caps produced |

18′-24′ single rib/double rib |

| Production speed | According to the thickness of the material, the best control is 90-120p/m (the machine life can be lasting, more than 150 will damage the mold). |

|

Weight of the whole machine |

450KG |

|

Adaptable material |

non-woven fabric (9-10g/m2) Rubber band model (30-40 yarn wrapping) |

Exhibition photos

Exhibition photos

Exhibition photos

The company has obtained more than 20 kinds of national new patents and software copyrights, which are in full compliance with export standards. Chuangying has complete processing equipment and efficient technical team; with its deep technical development strength, complete product guarantee system, sincere pre-sales advice and perfect after-sales service, it integratesdomestic and foreign electromechanical control technology into one. One of the automation service providers in the mask machine industry,home appliance industry, and sensor industry provides a strong backing for the high-efficiency, high-quality, and high-precision development of the machinery industry.

Falt mask machine production workshop

Kn95 mask machine production workshop

Four-side sealing packaging machine production workshopTo bag packaging machine production workshop

To bag packaging machine production workshop

preciseness, quality first and service second are our company's business philosophy. I hope the epidemic situation in South Korea

and the world will end as soon as possible. I hope we can work together for win-win results

FAQ

The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to

customer service for details.

2. The machine I want is too ?

inconsistent with what you showed on the Internet. 3.Can I do it?

Yes, you need to provide machine pictures and finished mask pictures.

4.what should I do if I buy a machine and Iwon’t install it back?South Korea and Vietnam have after-sales and can be installed on

site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only

need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and

operate normally. The company will be equipped with text version and video version of the whole teaching.

5. How long is the warranty period?

The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company

provides new parts.

Gather small fabrics

Along the direction of the fabric, we gather the fabric in the middle and fold it slowly, which is equivalent to a smaller cross-section.

Continue to save and fold, it looks smaller and smaller! Now form a small evenly folded strip, like a folding fan, and the rubber bands on both sides are still on the outermost side.

If it is a demo of the entire production, it will look like this, from right to left...

Tighten the fabric

The next step is to understand the difficulty...how to shrink such a large fabric into a small one. The key is - relax! The elastic bands on the most two sides were first pulled and stretched, and then welded together with the film. But once it is not stretched further, the elastic band will spring back, then the film will also be shrunk, and a long strip will be shrunk to the original length of the elastic band.