-

KN95 Face Mask Making Machine

-

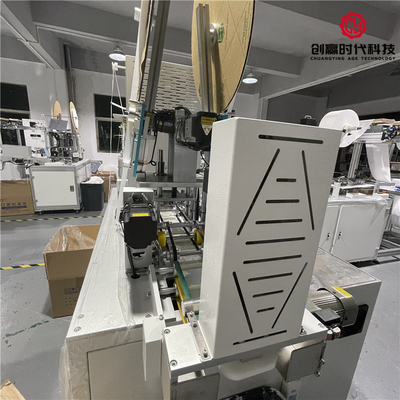

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

KF94 Nonwoven Disposable Mask Making Machine 120pcs/Min

| Applicable Industries | Manufacturing Plant | Showroom Location | South Korea |

|---|---|---|---|

| Condition | New | Automatic Grade | Full-automatic |

| Voltage | 220V | Power | 220 V |

| Dimension(L*W*H) | 2300mm*4900MM*2200MM | Weight | 1000KG |

| Warranty | 1 Year | Year | 2020 |

| Production Capacity | 120 Pcs/min | Key Selling Points | Easy To Operate |

| Mask Types | Flat | Mask Material | Non-woven Fabrics |

| Product Name | Mask Making Machine | Application | Making Disposable Face Mask |

| Final Products | Disposable Fabric Face Mask | Keywords | Nonwoven Fabric Proction Line |

| Function | Making Surgical Face Mask | Usage | Non Woven Products Making |

| Machine Type | Disposable Nonwoven Machinery | Name | Automatic Face Mask Line |

| Type | Nonwoven Fabric Line | Marketing Type | Hot Product 2020 |

| Local Service Location | South Korea | Port | Shenzhen Port, Qingdao Port |

| High Light | Nonwoven Disposable Mask Making Machine,Disposable Mask Making Machine 120pcs/Min,KF94 Nonwoven Mask Machine |

||

You are welcome to consult and negotiate. The mask machine is divided into: flat mask machine, kf94 mask machine, cup mask machine, flat fish mask machine, elastic ear band mask machine, kn95 mask machine. Various positioning pattern mask machines, customized machines according to the mask style you need. We specialize in customizing special mask machines. Packaging machines are divided into: bag-feeding packaging machine, four-side sealing packaging machine, three-side sealing packaging machine,counting machine and so on. And there are mask appearance inspection equipment, packaging machine, cartoning machine, sealing machine, and fully automated unmanned production mask line can be customized. The company established a mask factory in May 2021, and can now produce and export various masks. Welcome your consultation and inspection.

|

After-sales Service Provided

|

Field installation, commissioning and training, Free spare parts, Video technical support, Online support, Field maintenance and repair service

|

|

Dimensions

|

2300MM × 4900MM × 2200MM.

|

|

The quality of the whole machine

|

(approximately) 1000Kg.

|

|

After Warranty Service

|

Online support, Field maintenance and repair service, Spare parts, Video technical support

|

|

Expansion performance

|

can be connected to packaging equipment.

|

|

Use environment

|

ambient temperature 10-30 degrees Celsius, relative humidity less than 80%, no condensation, no dust, no corrosive gas, no strong

vibration source around the machine. |

Q: How long is the delivery time?

Answer: The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to customer service for details.

Question: The machine I want is too inconsistent with what you showed on the Internet. Can I do it?

Answer: Yes, you need to provide machine pictures and finished mask pictures.

Question: What should I do if I buy a machine and I won’t install it back?

Answer: South Korea and Vietnam have after-sales and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: How long is the warranty period?

Answer: The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company provides new parts.

The following information comes from the Internet for reference only

Full-automatic high-speed flat-type earband mask machine production line, including automatic raw material feeding, automatic conveying, cutting off the nose bridge, mask edge welding, folding, ultrasonic fusion, forming, cutting, conveying, automatic flipping, earband welding, automatic discharging, etc. The whole process is automated, and the entire production process from the raw material of the coil to the finished mask is completed. Its newly optimized one-to-one outer ear flat mask machine adopts advanced full servo system control and is jointly researched and developed by professional engineers. It is the current production speed, extremely high stability, and fully equipped mask equipment. It only needs to install the production raw materials. On the feeding rack, after the preparation is OK, the machine automatically produces. Only one person is required to operate the packaging. The full automatic production is fully realized. The equipment adopts ultrasonic welding, which is beautiful in style, hygienic and environmentally friendly. Features of automatic one-to-one high-speed mask machine

1. Automatic tension control of raw materials. Ensure that the tension of raw materials is balanced.

2. Photoelectric detection of raw materials to avoid errors and reduce waste.

3. Three-layer flat mask body can be produced, and the surface length of the finished product conveyor belt is 1200MM.

4. This flat face mask machine has the functions of total counting and batch counting, and the number of batch counting can be set arbitrarily.

5. The whole machine adopts sheet metal + aluminum alloy structure, which is beautiful and firm without rust.

6. Modular and user-friendly design to facilitate maintenance.

Equipment parameters of automatic one-to-one high-speed mask machine:

Production qualification rate: ≥98%

Equipment utilization rate: ≥98%

One for one 90-100 Pcs/Min

Operating voltage: AC220V±10%/50HZ

Equipment power: 9KW

Number of operators: 1 person is responsible for loading and unloading

Adapt to product specifications

The production object of the automatic one-to-one flat high-speed mask machine is a medical mask mainly composed of three layers of non-woven fabric, the outer layer is a non-woven fabric with waterproof treatment, which is mainly used to isolate the liquid sprayed by the patient, and the middle filter layer is used Is an electret-treated polypropylene meltblown non-woven fabric;

![]()

![]()