-

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

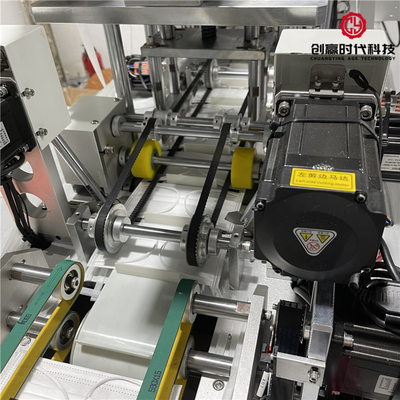

PLC 160pcs Non Woven Face Mask Making Machine Fully Automatic

| Applicable Industries | Manufacturing Plant | Showroom Location | South Korea |

|---|---|---|---|

| Condition | New | Automatic Grade | Full-automatic |

| Voltage | 220V | Power | 220 V |

| Dimension(L*W*H) | L4200mm*W1900mm*H1400mm | Weight | 1000KG |

| Warranty | 1 Year | Year | 2021 |

| Production Capacity | 120 Pcs/min | Key Selling Points | Easy To Operate |

| Mask Types | Flat | Mask Material | Non-woven Fabrics |

| Appearance Color | According To The Factory Standard | Equipment Weight | 800kg, Ground Bearing ≤ 500kg / M2 |

| Working Power Supply | 220 V, 50 Hz, Rated Power About 10 KW | Compressed Air | 0.5-0.7 MPa, The Flow Rate Is About 300 L / Min |

| Operating Environment | Temperature 10 ~ 35 ℃ | Number Of Servos | 14 |

| Delivery Date | Spot Delivery | Yachao Ultrasonic | 18K,2600W |

| Multilingual System | Customizable | High Speed Point Earphone Box | PLC Control |

| After Warranty Service | Online Support, Field Maintenance And Repair Service, Spare Parts, Video Technical Support | Local Service Location | South Korea |

| After-sales Service Provided | Field Installation, Commissioning And Training, Free Spare Parts, Video Technical Support, Online Support, Field Maintenance And Repair Service | Port | Shenzhen Port, Qingdao Port |

| High Light | 160pcs Non Woven Face Mask Making Machine,PLC Non Woven Face Mask Making Machine,Fully Automatic Nonwoven Mask Machine |

||

You are welcome to consult and negotiate. The mask machine is divided into: flat mask machine, kf94 mask machine, cup mask machine, flat fish mask machine, elastic ear band mask machine, kn95 mask machine. Various positioning pattern mask machines, customized machines according to the mask style you need. We specialize in customizing special mask machines. Packaging machines are divided into: bag-feeding packaging machine, four-side sealing packaging machine, three-side sealing packaging machine,counting machine and so on. And there are mask appearance inspection equipment, packaging machine, cartoning machine, sealing machine, and fully automated unmanned production mask line can be customized. The company established a mask factory in May 2021, and can now produce and export various masks. Welcome your consultation and inspection.

|

Power supply

|

AC 220V ±10% 50Hz 16A.

|

|

Dimensions

|

2300MM × 4900MM × 2200MM.

|

|

The quality of the whole machine

|

(approximately) 1000Kg.

|

|

Design capacity

|

80-100 pieces/minute.

|

|

Expansion performance

|

can be connected to packaging equipment.

|

|

Use environment

|

ambient temperature 10-30 degrees Celsius, relative humidity less than 80%, no condensation, no dust, no corrosive gas, no strong

vibration source around the machine. |

Q: How long is the delivery time?

Answer: The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to customer service for details.

Question: The machine I want is too inconsistent with what you showed on the Internet. Can I do it?

Answer: Yes, you need to provide machine pictures and finished mask pictures.

Question: What should I do if I buy a machine and I won’t install it back?

Answer: South Korea and Vietnam have after-sales and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: How long is the warranty period?

Answer: The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company provides new parts.

The following information comes from the Internet for reference only

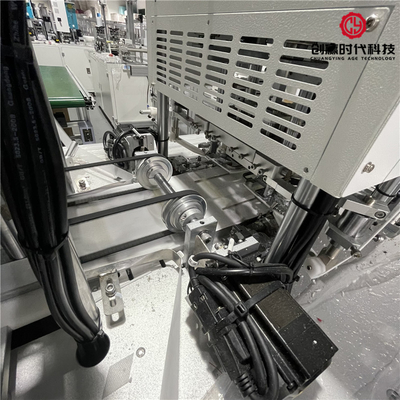

The fully automatic flat mask machine is a fully automatic mask production line developed by our company in order to fight the epidemic and concentrate technical resources to produce disposable multi-layer flat masks. The production line adopts a one-to-two integration scheme (1 automatic filming machine + 2 ear wire welding machines), and is controlled by computer PLC programming, which realizes automatic unwinding of raw materials, automatic conveying, cutting off the bridge of the nose, welding of mask edges, and ultrasonic fusion , Forming and cutting, ear wire welding and other full process automation, 24 hours full load capacity can reach 120,000 per day

The automatic flat face mask machine is composed of a host and two ear strap welding machines, connected by a one-in-two transmission line. Only one operator is required for each equipment to realize the automatic production process from coil feeding, folding and pressing to forming and slitting, welding and blanking of ear strap feeding machine, greatly improving production efficiency.

Scope of application

This machine is a fully automated production machine for folding flat mask body

Automatic unwinding of raw materials, automatic conveying, cutting off the bridge of the nose

Edge welding and folding of flat mask

Ultrasonic fusion; full process automation such as forming and cutting, high output

The pattern of the welding point of the plane mask body can be specified by the customer

Changing the mold can produce flat masks of different sizes and styles

Product performance

High stability and low failure rate

Computer PLC programming control, servo drive, advanced technology

Photoelectric (optical fiber) detection of raw materials to avoid errors and reduce waste

Automatic tension control of raw materials to ensure balanced tension of raw materials

Automatic tension control of non-woven roll material unwinding to ensure balanced feeding tension

Automatic tension control of non-woven roll material unwinding to ensure balanced feeding tension

Changing the mold can produce flat masks of different sizes and styles

The whole machine adopts aluminum alloy structure, which is beautiful and firm without rust.

![]()

![]()