-

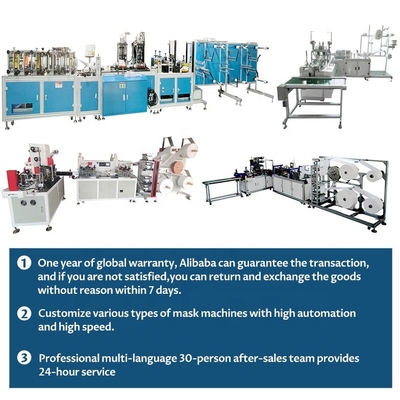

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

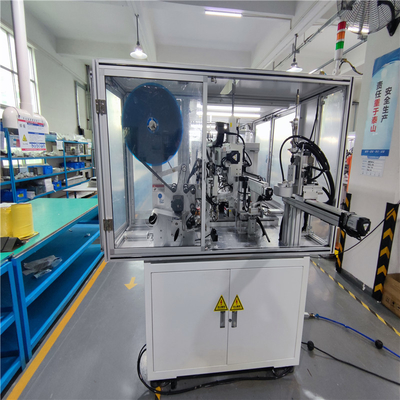

14kW N95 Cup Mask Cartoning Machine 180 Tablets Per Minute

| Place of Origin | Guangdong, China |

|---|---|

| Brand Name | chuangying |

| Certification | 1 set |

| Model Number | Cup mask |

| Minimum Order Quantity | 150 Set/Sets per Month |

| Price | $25,000.00/Sets 1-4 Sets |

| Packaging Details | Pack the wooden box after vacuum packing |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 150 Set/Sets per Month |

| Applicable Industries | Machinery Repair Shops, Manufacturing Plant, Other | Showroom Location | South Korea |

|---|---|---|---|

| Condition | New | Automatic Grade | Full-automatic |

| Voltage | 220V, 380V | Power | 14kW |

| Dimension(L*W*H) | 7699mm*2613mm*1726mm | Weight | 2400 KG |

| Warranty | 1 Year | Year | 2020 |

| Production Capacity | Other | Key Selling Points | Famous Brand PLC |

| Mask Types | Cup | Mask Material | Non-woven Fabrics |

| Product Name | Cup Mask Machine | Keywords | Ultrasonic Face Mask Making Machine |

| High Light | N95 Cup Mask Cartoning Machine,180 Tablets Per Minute Cup Mask Machine,14kW Cup Mask Cartoning Machine |

||

|

Model no.

|

DEYI

|

Servo Motor

|

THINGET (France)

|

|

Product name

|

Cup mask

|

Control System

|

DEYI

|

|

Mask Size

|

140mm×120mm×50mm

|

Ultrasonic Generator

|

220V, 20kHz, 1.5kW

|

|

Speed

|

12-15 pcs/min

|

Sensor

|

Panasonic(Japan)

|

|

Material

|

Non-woven fabric, Melt-blown fabric, Hot air Cotton,

Carbon fiber fabric, Mirco filter fabric, etc. |

Air Component

|

SMC(Japan) AIRTAC(Taiwan

|

|

Layers

|

3-6

|

Belt

|

(Japan)

|

|

Hot Pressed CupType

|

Cup Type Can be Customized

|

Main Base

|

DEYI

|

|

Ear Strap Fixed Typ

|

by Stapling (Staple Size:6-7mm L; 1mm W),

or by Ultrasonic Welding |

Cable

|

IGUS(Germany) ECHU(China)

|

|

Control Panel

|

10 inches touching screen control panel

|

Cable Carrier

|

THINGET(China)

|

|

Air Pressure

|

0.6MPa

|

Linear Guide

|

SILVER(Taiwan)

|

|

Power

|

14.5kW

|

Caster

|

GLOBE (China)

|

|

Power Supply

|

380V/50Hz

|

Ball Screw

|

HIWIN(Taiwan)

|

|

Machine Area

|

13m x 2.55m x 1.8m (L x W x H)

|

Safety Device

|

SICK(Germany)

|

![]()

![]()

![]()

![]()

Q: How long is the delivery time?

Answer: The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to customer service for details.

Question: The machine I want is too inconsistent with what you showed on the Internet. Can I do it?

Answer: Yes, you need to provide machine pictures and finished mask pictures.

Question: What should I do if I buy a machine and I won’t install it back?

Answer: South Korea and Vietnam have after-sales and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: How long is the warranty period?

Answer: The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company provides new parts.

The following information comes from the Internet for reference only

01 Introduction to the mask machine

The cup-shaped mask machine is a process of hot pressing, folding and forming, ultrasonic welding, waste removal, ear belt and nose strip welding of multi-layer non-woven fabrics to produce various masks with certain filtering performance. The mask equipment is not a single machine. It requires the cooperation of multiple machines to complete various processes.

Mask machines on the market now include: HD-0301 flat mask machine, HD-0304 cup mask machine, duckbill mask machine, folding mask machine, gauze mask machine, etc.

02 Mask production process

The entire production process of cup-shaped masks is relatively large, especially the subsequent disinfection process. This is why a mask is made in 0.5 seconds, so the production efficiency is still in short supply. To understand the mask production process, firstly, the structure of the mask itself Speaking of, when we cut a medical mask, we can find that the mask has three layers of non-woven fabric, which is also required by the national standard for medical masks, otherwise the protection requirements will not be met.

SMS non-woven fabrics make masks. All raw materials are polypropylene (PP). Medical masks are generally referred to as SMS structures. Among them, the spunbond layer is a single layer, and the meltblown layer can be divided into single layer or multiple layers according to filtration requirements. "Meltblown cloth" is commonly known as the "heart" of a mask. It is the filter layer in the middle of the mask. It has good filtering, shielding, heat insulation and oil absorption properties. It is an important raw material for the production of cup-shaped masks.

Polypropylene high-melt finger non-woven fabric is the best choice for masks. It can also be used in disposable surgical gowns, sheets, cover cloths, liquid absorbent pads and many other medical supplies. These materials come from some chemical companies such as Sinopec, Qilu Petrochemical, Zhenhai Refining and Chemical, Maoming Petrochemical.

With the supply of raw materials, the process of making masks is not so complicated.

03 Cup-shaped mask production process

1) Lay the three layers of non-woven fabric materials together through the machine

Finally, pass the quality inspection, and package the finished cup after sterilization

China's masks have already achieved assembly line production. Under normal circumstances, a machine can generally produce 2 to 3 masks per second. So why is there a shortage of masks on the market when there are raw materials? Because masks must be disinfected when they leave the factory. According to the official microblog of the Ministry of Industry and Information Technology: China’s production of masks is very fast, only 0.5 seconds per piece, but the standard process of analysis and disinfection after production takes 7 days to half a month.

The Ministry of Industry and Information Technology pointed out in the official microblog that medical cup-shaped masks are sterilized with ethylene oxide. After sterilization, there will be residues of ethylene oxide on the masks. The residual ethylene oxide must be released through analytical methods to achieve safety. The content standard can only be released on the market after passing the test.