-

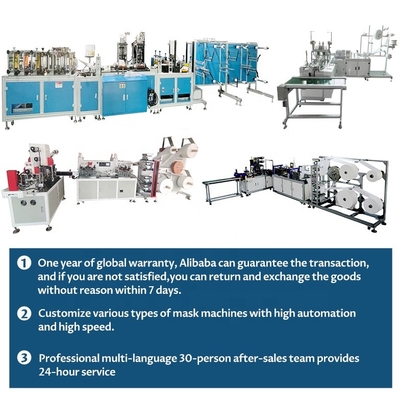

KN95 Face Mask Making Machine

-

KF94 Mask Machine

-

KN95 Mask Testing Equipment

-

Face Mask Packing Machine

-

Fish Mask Making Machine

-

Disposable Mask Making Machine

-

Lip Language Mask Machine

-

Cupped Face Mask Machine

-

Positioning Mask Machine

-

Melt Blown Cloth

-

Earloop Mask Machine

-

CNC Engraving Machine

-

Bag-feeding packaging machine

-

Cloth Iron And Folding Machine

-

Paper Container Making Machine

-

Semiconductor Wafer Chip

-

Disposable Medical Consumables

-

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

joeYour machine is very good, the service and after-sales service are very good, my team and I are very satisfied, and I will find you next time I buy

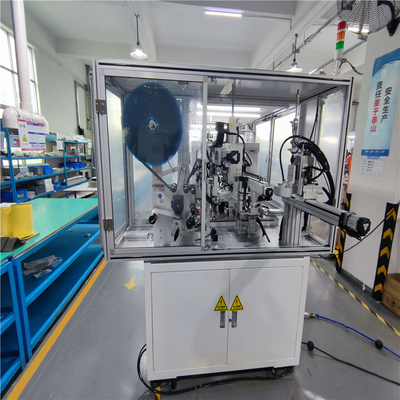

Full Automatic N95 Cup Mask Making Machine Ultrasonic PLC Control

| Applicable Industries | Machinery Repair Shops, Manufacturing Plant, Other | Showroom Location | South Korea |

|---|---|---|---|

| Condition | New | Automatic Grade | Full-automatic |

| Voltage | 220V, 380V | Power | 14 W |

| Dimension(L*W*H) | 7699mm*2613mm*1726mm | Weight | 2400 KG |

| Warranty | 1 Year | Production Capacity | Other |

| Key Selling Points | Famous Brand PLC | Mask Types | Cup |

| Mask Material | Non-woven Fabrics | Product Name | Cup Mask Machine |

| Keywords | Ultrasonic Face Mask Making Machine | ||

| High Light | N95 Cup Mask Making Machine,Full Automatic N95 Cup Mask Machine,Ultrasonic Cup Mask Making Machine |

||

|

Model no.

|

DEYI

|

Servo Motor

|

THINGET (France)

|

|

Product name

|

Cup mask

|

Control System

|

DEYI

|

|

Mask Size

|

140mm×120mm×50mm

|

Ultrasonic Generator

|

220V, 20kHz, 1.5kW

|

|

Speed

|

12-15 pcs/min

|

Sensor

|

Panasonic(Japan)

|

|

Material

|

Non-woven fabric, Melt-blown fabric, Hot air Cotton,

Carbon fiber fabric, Mirco filter fabric, etc. |

Air Component

|

SMC(Japan) AIRTAC(Taiwan

|

|

Layers

|

3-6

|

Belt

|

(Japan)

|

|

Hot Pressed CupType

|

Cup Type Can be Customized

|

Main Base

|

DEYI

|

|

Ear Strap Fixed Typ

|

by Stapling (Staple Size:6-7mm L; 1mm W),

or by Ultrasonic Welding |

Cable

|

IGUS(Germany) ECHU(China)

|

|

Control Panel

|

10 inches touching screen control panel

|

Cable Carrier

|

THINGET(China)

|

|

Air Pressure

|

0.6MPa

|

Linear Guide

|

SILVER(Taiwan)

|

|

Power

|

14.5kW

|

Caster

|

GLOBE (China)

|

|

Power Supply

|

380V/50Hz

|

Ball Screw

|

HIWIN(Taiwan)

|

|

Machine Area

|

13m x 2.55m x 1.8m (L x W x H)

|

Safety Device

|

SICK(Germany)

|

![]()

![]()

![]()

Q: How long is the delivery time?

Answer: The general situation is 3-5 days for delivery. If you need a customized mask shape, it will take 7-10 days. Please refer to customer service for details.

Question: The machine I want is too inconsistent with what you showed on the Internet. Can I do it?

Answer: Yes, you need to provide machine pictures and finished mask pictures.

Question: What should I do if I buy a machine and I won’t install it back?

Answer: South Korea and Vietnam have after-sales and can be installed on site. Other countries can send installation videos and remote video guidance. Many foreign customers install this way. You only need to install the four screws of the connector of the filming machine and the earband machine, learn to load the cloth and operate normally. The company will be equipped with text version and video version of the whole teaching.

Q: How long is the warranty period?

Answer: The warranty period is one year. The ultrasound is three months. During the warranty period, the parts are damaged and the company provides new parts.

The following information comes from the Internet for reference only

Cup mask machine

What is the process of using a mask machine to produce masks?

Production process of flat masks:

Non-woven step belt feeding and edging — hot pressing — folding forming — ultrasonic earband welding — nose bridge welding — waste removal — finished product output — sterilization — analysis

Production process of N95 cup mask (with breathing valve):

Feeding and edging — hot pressing — manufacturing outer face mask — welding and trimming — mask printing — breathing valve perforation — nose bridge strip welding — pasting inner nose bridge — welding ear bands — welding breathing valve — cup-shaped finished product output — extinguish Bacteria — analysis

Mask machine can produce masks,

What technologies and job knowledge are used in the cup mask machine?

1. Process technology: there must be a detailed process flow, that is, a complete set of action flow

For example, how to start feeding, how to wrap the edges after feeding, and how to shape next...

This process is provided by: [Process Engineer]

2. Mechanical technology: With a complete action process, [mechanical engineer] can design the mechanical structure corresponding to the action, such as useful material tray mechanism, guide mechanism, roller mechanism, spur gear, bearing, sprocket and roller mechanism , Flip mechanism, cam split mechanism, wire drawing welding mechanism, shearing mechanism, conveying mechanism, etc.

This part is designed and completed by: [mechanical engineer]

3. Electrical technology: After the mechanical structure has been established, it needs to be driven and driven by electrical actuators to move it.

For example, the conveyor belt is driven by a motor and a frequency converter, and the cutting positioning is driven by an air cylinder or servo or stepping.

The electrical control programming part uses PLC, touch screen programming control, and also uses the frequency converter, motor, stepping system, servo system, solenoid valve, cylinder, sensor, temperature analog and other technologies

This part is designed and completed by: [Electrical Engineer]