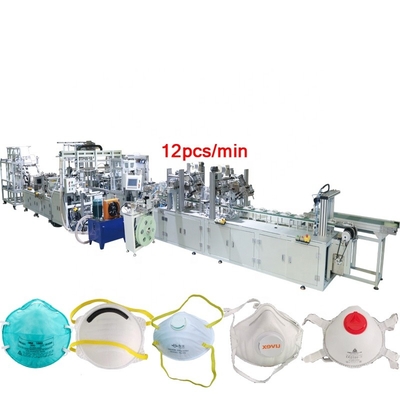

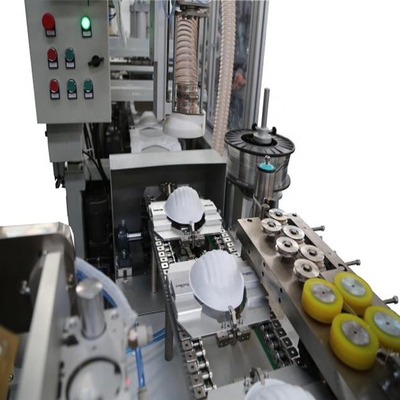

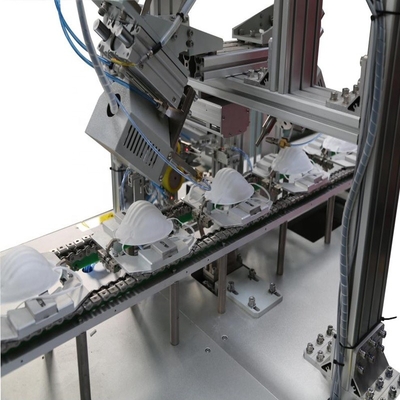

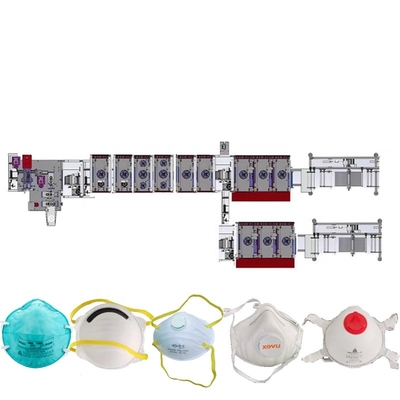

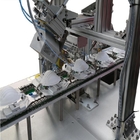

The automatic coat forming automatic cup production line with independent property rights is the first automatic production line for producing cup masks in China. All kinds of technology are available.

Cup masks have the following advantages over flat masks:

1. Unique cup shape design, better sealing between mask and face, dust and virus cannot leak in easily;

2. Ergonomic nose design can increase the comfort of wearing.

3. Cup masks are generally worn on the head for better comfort 4.Wear process is not easy to deformation, good protection performance.