|

Model no.

|

DEYI

|

Servo Motor

|

THINGET (France)

|

|

Product name

|

Cup mask

|

Control System

|

DEYI

|

|

Mask Size

|

140mm×120mm×50mm

|

Ultrasonic Generator

|

220V, 20kHz, 1.5kW

|

|

Speed

|

12-15 pcs/min

|

Sensor

|

Panasonic(Japan)

|

|

Material

|

Non-woven fabric, Melt-blown fabric, Hot air Cotton,

Carbon fiber fabric, Mirco filter fabric, etc. |

Air Component

|

SMC(Japan) AIRTAC(Taiwan

|

|

Layers

|

3-6

|

Belt

|

(Japan)

|

|

Hot Pressed CupType

|

Cup Type Can be Customized

|

Main Base

|

DEYI

|

|

Ear Strap Fixed Typ

|

by Stapling (Staple Size:6-7mm L; 1mm W),

or by Ultrasonic Welding |

Cable

|

IGUS(Germany) ECHU(China)

|

|

Control Panel

|

10 inches touching screen control panel

|

Cable Carrier

|

THINGET(China)

|

|

Air Pressure

|

0.6MPa

|

Linear Guide

|

SILVER(Taiwan)

|

|

Power

|

14.5kW

|

Caster

|

GLOBE (China)

|

|

Power Supply

|

380V/50Hz

|

Ball Screw

|

HIWIN(Taiwan)

|

|

Machine Area

|

13m x 2.55m x 1.8m (L x W x H)

|

Safety Device

|

SICK(Germany)

|

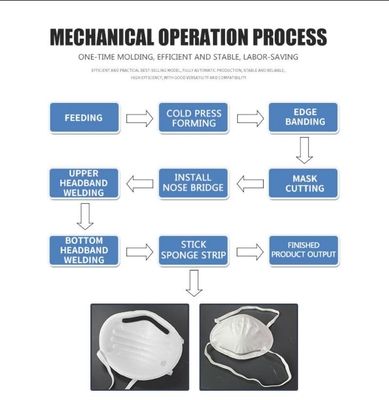

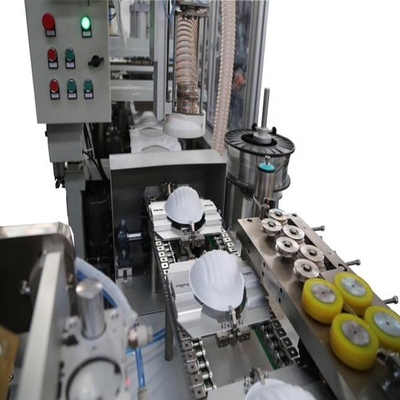

The all-in-one machine for the rear section of the cup mask is fully automated. It is inserted from the body of the cup mask without damaging the material and ensuring the filtering function. The equipment is automatically shifted and punched, the periphery is uniform, and the compression is strong. The mask body is active after the active displacement The nose bridge welding, active printing of LOGO, active punching edge, active breathing valve welding, active ear belt spot welding and other processes are actively connected, and then the cup-shaped mask is automatically produced. The whole machine completes the automatic operation, and the power is traditional More than three times the technology, the machine is advanced and sophisticated. technical parameter:

Machine size: 5000mm*1700mm*2000mm

Weight: 1500KG power

Capacity: 40-50pcs/min

Voltage: 220V

Air pressure: 3-7kg/cm²)

Frequency: 15/25KHZ

Power: 8000W

Machine features:

1. Integrated planning, raw materials enter the product output, and work actively throughout the process.

2. Active constant pressure shaping, no damage to the material, easy to pass the filtering function.

3. Servo shift, precise positioning, imported cutters, smooth trimming.

4. Integrated manufacturing with several processes, reasonable planning and higher power.

4.Wear process is not easy to deformation, good protection performance.